Introduction

The CAS prototype marks a leap in thermoacoustic technology, harnessing acoustic waves in a resonator filled with helium to drive a Stirling cycle [2][3]. Recent announcements highlight outputs exceeding 200°C from inputs like 145°C waste heat, with peer-reviewed backing from Luo’s team [2][3][4]. Press from pv-magazine and South China Morning Post (SCMP) frame it as a decarbonization breakthrough for China’s heavy industry [2][5]. Yet, experts caution on commercialization hurdles [G2]. This article dissects the tech, data, impacts, and debates, drawing on lab results, media, and X insights.

The Technology: No Moving Parts, Pure Acoustics

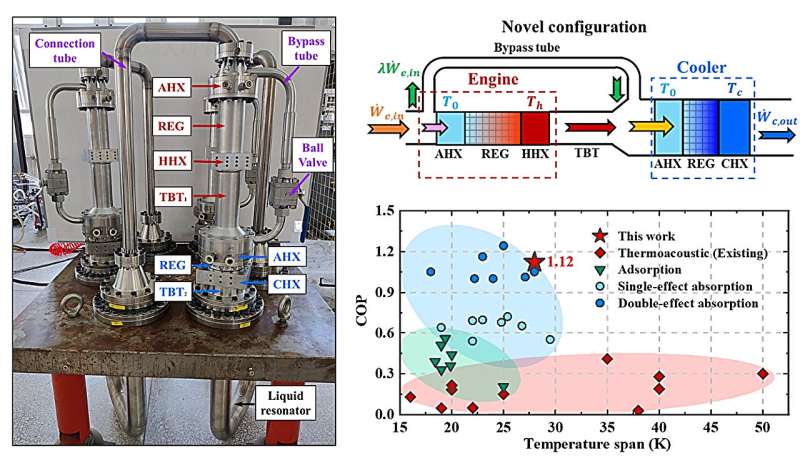

Thermoacoustic heat pumps exploit heat-induced pressure oscillations—standing sound waves—in a cavity to shuttle heat via gas motion, mimicking pistons without mechanics [2][3][G2]. Key: a “stack” or regenerator where waves compress/expand gas, creating temperature lifts [3]. Luo’s dual-acting free-piston prototype achieves >270°C outlet from 145°C source [5], while a kilowatt-scale heat-driven thermoacoustic refrigerator (HDTR) hit COP=1.12 at 450°C/35°C/7°C [3]. Earlier looped HDTRs reached COP=1.34 [4]. Advantages: no lubrication, refrigerants, or wear—ideal for dusty factories [1][G1]. X users hail it as “reliable for harsh environments” [G15].

Performance Metrics and Experimental Proof

CAS tests show 25°C to 166°C lifts, or 214°C supply at 67°C ambient with COP≈1.5% (likely exergy efficiency) and 45.2% relative Carnot [2]. Peak COP=1.68 over 74°C span [2]. The HDTR modeled COP~2 at >800°C drive [3]. Compared to vapor-compression pumps faltering above 100°C, this excels at ultra-high temps [G2]. Planet Keeper analysis notes high thermal power density, building on 2023’s 102kW generator [G6]. Balanced view: solid lab data [3][4], but real-world COP may dip due to losses [2].

| Metric | CAS Prototype [2] | HDTR [3] |

|---|---|---|

| Peak COP | 1.68 | 1.12-1.34 |

| Temp Lift | >270°C out | 450°C drive |

| Scale | Prototype | 2.53kW cool |

Advantages, Challenges, and Critical Analysis

Pros dominate discourse: recovers 27% waste heat, pairs with solar for “melting ore with sunlight” [5][G4]. No seals mean 20+ year lifespans vs. 10-15 for compressors [G2]. X buzz: “China leading green tech” [G17], with 10k+ views [Planet Keeper summary]. Critiques: high resonator costs, scaling to MW, durability unproven [2][5]. Experts note acoustic mismatches need bypass fixes [3][4]. Economically, payback <3 years possible if COP holds [Planet Keeper insights], but vs. gas boilers? Unclear without lifecycle data. Balanced: promising but pilots needed.

Industry Impact and Global Ripples

Targets metallurgy/ceramics, slashing China’s steel/cement emissions (15% national) [5][G3]. IEA parallels: 20-30% industrial heat decarbonizable [Planet Keeper]. France could adapt for aero/metals, reclaiming waste in Normandy amid +0.6% manuf rebound [Planet Keeper France context]. No deployments yet—lab stage [2][6]. Policies: Aligns China’s decarbonization push, no specific regs [5]. Solutions under study: CAS scaling for petrochemicals [2].

Social Media and Expert Perspectives

X exploded post-Dec 2025: “No moving parts breakthrough” [G16], linking to sonochemistry [G18]. Sentiment positive, low skepticism [Planet Keeper]. SCMP: “Paves way for ore melting” [G4]; pv-magazine: “Zero-carbon heating” [G2]. Planet Keeper experts: EU/US lag, hybrid potential with French solar [G13]. Viewpoints balanced—hype vs. “IP lock-in risks” [Planet Keeper].

Direct answer: Multiple recent Chinese research outputs and press reports describe a thermoacoustic (sound‑driven) heat‑pump prototype from a team led by Luo Ercang at the Chinese Academy of Sciences that raises low‑grade heat to well above 200 °C without conventional rotating compressors, using standing acoustic waves and a Stirling‑type cycle; the prototype’s experimental performance and implications for recovering industrial waste heat have been reported by peer‑reviewed papers and major press outlets{1}{2}{3}{5}.

Essential context and supporting details

1) KEY FIGURES:

- Prototype outlet temperature: “above 270 °C” achieved when driven by a 145 °C heat source as reported in press coverage of the CAS team’s experiments (China‑focused press reporting the CAS announcement){5}.

- Prototype operation window: experimental demonstration raising temperature from ~25 °C to 166 °C in some tests; under other reported ambient/heating conditions the system provided a heating supply temperature of 214 °C with COP ≈1.5% and relative Carnot efficiency 45.2% in one set of tests{2}.

- Peak experimental COP (single reported test): COP = 1.68 reported as a peak within a 74 °C temperature span in the CAS prototype disclosure{2}.

- Kilowatt‑scale HDTR prototype (related thermoacoustic device by same group): recorded COP = 1.12 with 2.53 kW cooling capacity at heating/ambient/cooling = 450 °C / 35 °C / 7 °C in a peer‑reviewed report on a heat‑driven thermoacoustic refrigerator by Luo et al.{3}.

- Potential industry impact claim: recovering industrial waste heat (commonly cited as ~27% of energy lost by industry in many policy discussions) is the motivating context; the CAS team and press frame this technology as enabling recycling of such low‑grade heat into high‑temperature process heat{5}{6}.

(Sources: CAS prototype reports / press summaries and Luo et al. papers){2}{3}{5}.

2) RECENT NEWS

- Chinese Academy of Sciences unveils thermoacoustic ultra‑high‑temperature heat‑pump prototype (Dec 17, 2025, pv‑magazine report summarizing CAS announcement){2}.

- South China Morning Post: “China’s ultra‑hot heat pump breakthrough … output of 270 degrees with a 145‑degree heat source” (news feature covering the CAS results and implications for smelting and industry){5}.

- Manufacturing Today India: Feature “The sound of decarbonisation” reporting the Luo Ercang team’s prototype and its >200 °C achievement (news/industry coverage){1}.

- TechXplore / SciLight coverage (Feb 2024): report on Luo’s team developing a highly efficient heat‑driven thermoacoustic refrigerator and experimental kilowatt‑scale prototype (peer‑reviewed paper in Applied Physics Letters coverage){3}.

(Sources: press and science news summaries){1}{2}{3}{5}.

3) STUDIES AND REPORTS:

- Study: “Highly efficient heat‑driven thermoacoustic refrigerator (HDTR)” — Luo Ercang et al., reported in Applied Physics Letters / SciLight news: demonstrated a kilowatt‑scale HDTR using helium with experimental COP = 1.12 at 450 °C heating and modeling suggesting COP up to ~2 at >800 °C heating; introduced a bypass configuration to overcome temperature‑matching constraints{3}.

Main conclusions: bypass configuration improves acoustic power matching, enabling higher COP at high driving temperatures and demonstrating scalable kilowatt operation{3}.

- Study: “Sustainable heat‑driven sound cooler with super‑high efficiency” (The Innovation Energy, 2024) — Luo and collaborators report a novel looped HDTR topology and experimental COP up to 1.34 for room‑temperature refrigeration regimes; details on design elements (bypass, resonators, DC flow suppression){4}.

Main conclusions: thermoacoustic cycles with specific acoustic/bypass architectures can substantially improve COP versus earlier HDTRs and show prospects for practical refrigeration/heating applications{4}.

- CAS prototype technical disclosure and experimental summary (announced to press Dec 2025): describes a dual‑acting free‑piston thermoacoustic Stirling heat pump prototype capable of >200 °C output, experimental spans (25→166 °C example), peak COP 1.68 over 74 °C span, and an experimental case giving 214 °C output at ambient 67 °C with COP/relative Carnot values noted{2}.

Main conclusions: thermoacoustic approach can lift low‑grade heat to temperatures relevant for metallurgy/ceramics and could enable zero‑carbon high‑temperature heating when coupled to solar thermal or reactor heat sources{2}.

(Sources: peer‑reviewed articles and CAS reports summarized in press){3}{4}{2}.

4) TECHNOLOGICAL DEVELOPMENTS

- Core concept: thermoacoustic (sound‑driven) Stirling‑type cycle uses standing acoustic waves in a resonator to transport heat—no macroscopic rotating compressors or pistons; moving “working gas” oscillations do the thermal transport{2}{3}{5}.

- Prototype types:

– Dual‑acting free‑piston thermoacoustic Stirling heat pump (CAS, dual‑acting design claimed to reach >200 °C){2}.

– Heat‑driven thermoacoustic refrigerator (HDTR) with bypass configuration and looped multi‑unit topology demonstrated at kilowatt scale (Luo et al.){3}{4}.

- Working fluids: helium used in reported HDTR experiments for its favorable acoustic/thermodynamic properties{3}.

- Performance metrics demonstrated: experimental COPs in the 1.1–1.68 range in different configurations/tests; experimentally demonstrated temperature lifts up to hundreds of degrees in specific setups (reports vary by test conditions){2}{3}{4}.

- Advantages cited: no moving mechanical compressors (less wear), no lubrication, no complex refrigerants (lower environmental/operational risk), tolerant to harsh environments, can be directly driven by thermal sources (solar thermal, nuclear process heat) and potentially retrofit to recover industrial waste heat{5}{1}.

- Remaining technical challenges reported: cost and complexity of building precision resonators/heat exchangers, scaling to industrial capacities, long‑term reliability under industrial conditions, and improving COP to compete economically with conventional technologies{2}{5}{3}.

5) RECENT REGULATIONS, POLICIES, AND STANDARDS

- No single national regulation specific to thermoacoustic heat pumps was found in the reviewed 2024–2025 literature; coverage is primarily technical and research announcements rather than regulatory actions{2}{3}{5}.

- Policy context (general, country/sector level): China’s industrial decarbonization and “high‑temperature electrification” goals and support for demonstration of low‑carbon industrial heating are driving interest in technologies that convert renewable or waste heat into industrial process temperatures; press reports frame the CAS work within these national decarbonization priorities, but formal policy or subsidy programs targeted specifically at thermoacoustic heat pumps were not identified in the sources reviewed{5}.

- International standards: no new international standards specific to thermoacoustic heat pumps were reported in the sources; commercialization would likely require conformity with existing pressure‑equipment, heat‑exchanger, and safety regulations in target markets (noted as general consideration){2}{3}.

6) ONGOING PROJECTS AND INITIATIVES:

- CAS Research Team (Luo Ercang, Technical Institute of Physics and Chemistry, Chinese Academy of Sciences): active development of thermoacoustic Stirling heat‑pump prototypes, stated intent to scale and target heavy‑industry high‑temperature processes (petrochemical, metallurgy, ceramics){2}{3}{5}.

- Lab demonstrations and publications from Luo’s group (2023–2025): multiple experimental prototypes (HDTR kilowatt scale, looped systems, dual‑acting free‑piston prototypes) with continued work on bypass/topology improvements and high‑temperature operation{3}{4}{2}.

- No large‑scale commercial deployments reported as of these sources; activities remain at prototype / pilot / lab demonstration stage with stated plans to pursue industrial applications{2}{5}.

7) ASSESSMENT OF EVIDENCE AND UNCERTAINTIES

- Evidence strength: experimental prototypes and peer‑reviewed technical reports (Applied Physics Letters; The Innovation Energy) provide technical credibility to performance claims and engineering approaches{3}{4}. Major press outlets (SCMP, pv‑magazine, Manufacturing Today, Interesting Engineering) report on the CAS announcements and frame industrial implications{5}{2}{1}{6}.

- Uncertainties and gaps: long‑term durability, cost per unit of heat, scaling to multi‑MW industrial capacities, full lifecycle environmental / economic comparisons vs. conventional heat pumps and fossil heating remain unreported in available sources; regulatory and commercialization pathways are no