Introduction

The plastic crisis is unrelenting: over 70 million tons of PET are produced annually, with much ending up in landfills or oceans. Enzyme-based recycling, which uses biologically engineered proteins to break down PET into its building blocks—terephthalic acid and ethylene glycol—offers a sustainable alternative to energy-intensive mechanical or chemical processes. Recent 2025 studies highlight dramatic improvements in efficiency and cost, but experts warn of barriers like enzyme stability and industrial scaling. This article synthesizes factual data from institutions like NREL and UT Austin, alongside analytical perspectives from web analyses and social media sentiment, to provide an objective overview of this evolving field [1][G10].

Key Advancements in Enzyme Engineering

2025 has seen remarkable strides in enzyme design, driven by AI and synthetic biology. The FAST-PETase enzyme, developed by University of Texas researchers, depolymerizes contaminated and colored PET waste within hours at mild temperatures around 30°C, enabling high monomer recovery for reuse [2]. Similarly, the LCC-ICCG-C09 variant boasts a 3.5°C increase in thermal stability and doubles hydrolysis efficiency, operating optimally at 68°C for amorphous PET [4]. These innovations address previous limitations, allowing degradation of diverse waste streams, including textiles and bottles.

Whole-cell biocatalysts, such as yeast engineered to display PETase and MHETase enzymes, achieve complete depolymerization without intermediates, with reusability across cycles [3]. NREL’s process optimizations further integrate these with reduced chemical inputs, cutting acid/base additives by over 99% and energy use by 65% [1]. As noted in a Nature Communications article, standardization guidelines are crucial for comparing enzyme performance under industrial conditions, enhancing reproducibility [6].

Expert analyses emphasize AI’s role: machine learning accelerates directed evolution, creating variants for crystalline PET [G7]. Posts on social media reflect excitement, with users highlighting enzymes like “KUBU-M12” for rapid breakdown [G16].

Economic and Environmental Benefits

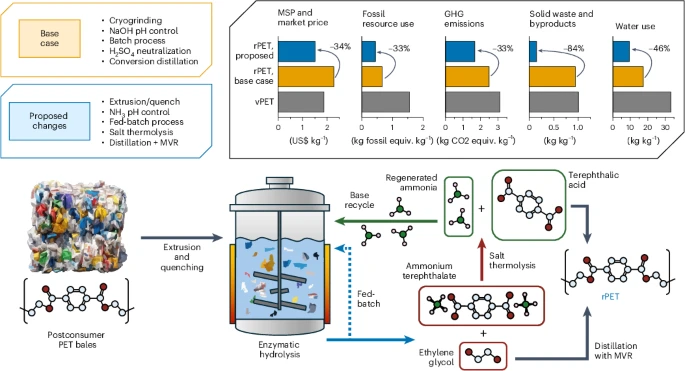

Enzymatically recycled PET (rPET) is gaining economic traction, with market projections reaching USD 89.6 billion by 2035, driven by sustainability demands [G8]. NREL’s 2025 study shows annual running costs dropping 74%, making rPET competitive with virgin plastics priced at US$1.87/kg [1].

Environmentally, these methods lower greenhouse gas emissions. A tandem enzymatic-electro upcycling study converts PET into high-value chemicals, supporting net-negative emissions [G13]. Analysts suggest a “bio-petro hybrid” model, where recycled monomers supplement virgin production, shifting geopolitics toward biotech-strong nations [G11].

Some argue costs remain high for low-value wastes, requiring subsidies [G3]. Social media discussions echo this, noting enzyme production bottlenecks [G18].

Persistent Challenges and Criticisms

Scalability is a core hurdle. Enzymes struggle with highly crystalline or mixed plastics, and producing them at volume is costly [5]. A 2025 Lightsources.org study confirmed efficiency drops with contaminated waste [5].

Critics point to technical limits like byproducts and enzyme deactivation in harsh conditions [G5]. Balanced perspectives online highlight realism: breakthroughs excite, but scalability remains limited [G20].

Constructive Solutions and Ongoing Initiatives

Collaborative projects, like NREL’s with University of Portsmouth, trial industrial-scale processes [1]. The EU’s upPE-T project optimizes PETase for upcycling [G12]. AI-driven design promises thermostable enzymes for complex wastes [G11].

Policy support from DOE and EU aligns with circular economy goals [1]. Experts advocate hybrid approaches—enzymes with electro-upcycling—for closed-loop systems [G13].

KEY FIGURES

- Enzymatic PET recycling reduces energy use by 65% and annual running costs by 74% compared to conventional methods, mainly by minimizing acid/base chemical additives by over 99% (NREL, 2025)[1].

- Engineered enzymes like FAST-PETase can depolymerize PET plastics—including contaminated and colored waste—within hours to days at relatively low temperatures (around 30°C), enabling efficient monomer recovery for reuse[2][3].

- The LCC-ICCG-C09 engineered enzyme variant shows a 3.5°C increase in thermal stability and doubles PET hydrolysis efficiency compared to previous standards, operating optimally at 68°C[4].

RECENT NEWS

- June 2025: NREL and partner institutions announced a breakthrough in enzyme-based PET recycling, achieving significant reductions in energy consumption and cost, with a roadmap toward industrial-scale deployment[1].

- April 2022: University of Texas researchers developed FAST-PETase, an AI-designed enzyme variant that rapidly degrades post-consumer PET waste, demonstrating potential to address billions of tons of landfill plastic[2].

- January 2025: A global study profiled microbial PET-degrading enzymes, highlighting advances in engineering enzymes that perform well under industrial recycling conditions, including harsh environments[5].

STUDIES AND REPORTS

- NREL-led study (2025) combined enzyme engineering with chemical process optimization and techno-economic analysis, showing enzymatic recycling can be economically viable at scale by reducing chemical inputs and energy use[1].

- ACS Environmental Science & Technology Letters (2023) demonstrated a yeast-based whole-cell biocatalyst displaying PETase and MHETase enzymes, achieving complete PET depolymerization at 30°C with reusable catalysts, marking progress toward circularity[3].

- FEBS Journal (2025) reported on the LCC-ICCG-C09 mutant enzyme with enhanced thermostability and catalytic efficiency, suggesting industrial applicability for enzymatic PET recycling[4].

- Lightsources.org (2025) described a landscape profiling method for microbial PET hydrolases, emphasizing the potential of enzyme engineering combined with synthetic biology and AI to overcome limitations of chemical recycling[5].

TECHNOLOGICAL DEVELOPMENTS

- FAST-PETase: An AI-designed enzyme variant with improved activity and stability, capable of rapidly depolymerizing diverse PET waste streams at mild temperatures, including post-consumer bottles and fibers[2][3].

- Whole-cell biocatalysts: Engineered yeast displaying multi-enzyme complexes (PETase + MHETase) to achieve full PET monomer recovery without intermediates, with potential for multiple reuse cycles[3].

- LCC-ICCG-C09: Rationally designed enzyme with enhanced thermal tolerance and activity, enabling efficient hydrolysis of amorphous PET at elevated temperatures for industrial processes[4].

- Process improvements integrating enzyme catalysis with reduced chemical inputs, optimized reaction conditions, and advanced separations technologies to lower costs and energy demands at scale[1].

CURRENT REGULATIONS AND POLICIES

- While specific regulatory frameworks for enzymatic plastic recycling are still evolving, there is increasing governmental and industrial interest in circular economy policies promoting chemical and enzymatic recycling pathways to meet plastic waste reduction targets.

- Agencies such as the U.S. Department of Energy and European Union environmental programs are funding research initiatives focused on enzyme-based recycling technologies as part of broader sustainability and plastic waste management policies[1].

ONGOING PROJECTS AND INITIATIVES

- Collaborative efforts between NREL, University of Massachusetts Lowell, and University of Portsmouth advancing industrial-scale enzyme recycling processes, including pilot demonstrations integrating biochemical and chemical engineering approaches[1].

- University of Texas-led project developing and optimizing FAST-PETase, leveraging machine learning and synthetic biology for enhanced enzyme variants applicable to real-world plastic waste streams[2].

- Industry partnerships exploring commercialization of enzymatic recycling technologies, aiming to retrofit or complement existing plastic waste management infrastructure for improved circularity[1][5].

MAIN SOURCES

- https://www.nrel.gov/news/detail/program/2025/plastics-recycling-with-enzymes-takes-a-leap-forward — NREL news on enzyme-based PET recycling process improvements (2025)

- https://news.utexas.edu/2022/04/27/plastic-eating-enzyme-could-eliminate-billions-of-tons-of-landfill-waste — UT Austin news on FAST-PETase development (2022)

- https://pubs.acs.org/doi/10.1021/acs.estlett.5c00190 — ACS Environmental Science & Technology Letters on whole-cell biocatalysts for PET depolymerization (2023)

- https://pubmed.ncbi.nlm.nih.gov/40847613/ — FEBS Journal article on engineered LCC-ICCG-C09 enzyme for PET recycling (2025)

- https://lightsources.org/2025/01/09/the-worlds-most-efficient-pet-degrading-enzyme/ — Landscape profiling and enzyme engineering advances (2025)

—

Summary: Enzyme-based PET recycling has achieved major milestones in reducing energy use (up to 65%) and running costs (up to 74%) through advanced enzyme engineering (e.g., FAST-PETase, LCC-ICCG-C09) and process optimization, allowing rapid, efficient depolymerization of contaminated and colored PET waste into high-quality monomers. Whole-cell biocatalysts further enhance depolymerization completeness and reusability. Despite these advances, challenges remain in scaling enzyme production cost-effectively and handling complex real-world waste streams. Ongoing industrial collaborations and governmental interest signal strong momentum toward commercial-scale deployment, positioning enzyme recycling as a disruptive alternative to petrochemical-based virgin plastic production and traditional recycling methods[1][2][3][4][5].